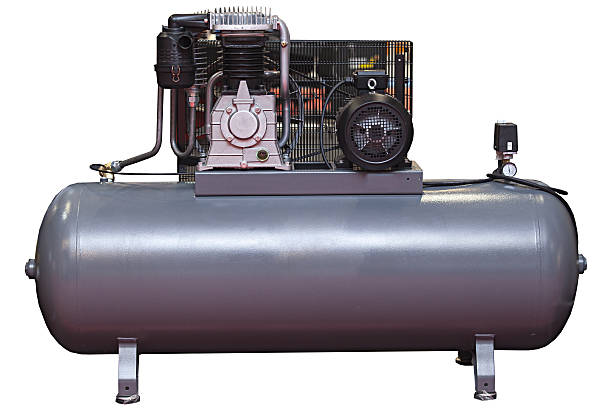

What Are The Characteristics Of An Air Compressor?

Now that you know the most common activities an air compressor uses let’s talk about the types of compressors. There is a wide range of models and brands on the market. However, it is essential to emphasize that it is necessary to know for what purpose the air compressor will be used to start your research.

Some models meet the simplest to the most complex needs. You must research the model, brand, and product warranty to choose the right one. After all, if your need is more complex, it is essential to find an air compressor with a good origin.

PSI – Air Pressure

When researching your air compressor that uses Online compressed air pressure drop calculator, you will notice on the data sheet the acronym PSI, which stands for air pressure. The vast majority of equipment needs 90 PSI to function correctly. So keep an eye out for that. Thus, the product description will show how much air pressure the compressor has. In addition, air compressors have two stages. The first stage is up to 90 PSI; in the second stage, the equipment can be up to 175 PSI.

A vital tip: Before using your air compressor, ensure nothing is restricting its air hose. If you have something blocking the air passage, it can make it difficult for the air pressure to reach the proper capacity.

HP – Power

The power of the air compressor is one of the things you need to be more aware of when buying. Power is the compressor’s force, which will define how strong the equipment is. The common power rating of an air compressor is 1.5 and 6.5 HP. Air compressors with higher HP capacity are reserved for industrial use, which, in addition to higher HP, also offer higher PSI. If your goal is a compressor for low-complexity use, you don’t need to look for one with power as high as those for industrial use.

CFM – Cubic Feet per Minute

The CFM is what evaluates the volume of air that an air compressor produces. Thus, CFM appears in various ratings at various pressures of a compressor. You might notice a high displacement CFM rating, for example. This is a rating based on the size and speed of the air compressor pump. However, it is unimportant as it is at zero pressure and does not account for pump inefficiencies.

An essential CFM on smaller compressors is 90 PSI, which is the pressure needed to operate most equipment. It’s essential to be aware that CFM ratings tend to be slightly exaggerated. So, to choose correctly, consider that you should have 3 – 4 CFM per real HP at 90 PSI.